Repmold: A Practical Approach to Faster and Smarter Mold Manufacturing

Repmold is quickly gaining attention in modern manufacturing because it offers something every production team wants: speed without sacrificing accuracy. As industries move toward shorter product cycles and tighter quality standards, traditional mold-making methods often struggle to keep up. Repmold fills this gap by providing a smarter, more flexible way to produce molds efficiently.

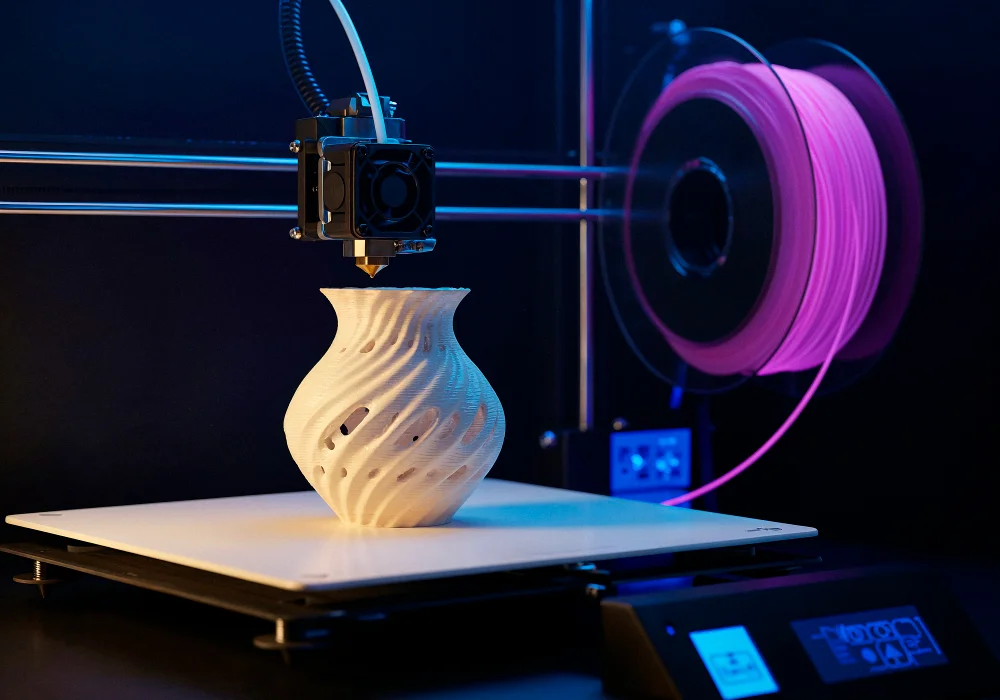

At its core, repmold is not about complexity—it is about control. By combining digital design, 3D printing, and advanced molding materials, repmold allows manufacturers to create reliable molds in days instead of months. This shift has changed how businesses approach prototyping, testing, and even small-scale production.

From innovative startups to established industrial manufacturers, repmold has become a trusted solution for reducing costs, improving consistency, and supporting modern automation workflows.

What Is Repmold?

Repmold is a modern replication molding process designed to create accurate molds and parts using digital manufacturing tools. The process typically begins with a 3D digital design, which is then converted into a physical master model through 3D printing. A mold is formed around this master using materials such as silicone, resin, or composites, allowing identical parts to be reproduced efficiently.

Compared to traditional metal tooling, repmold significantly reduces development time and investment. This makes it especially useful for rapid prototyping, low-volume production, and functional testing across multiple industries.

See also V48M 2898 IC: A Comprehensive Overview

How Repmold Evolved Over Time

Before repmold, manufacturers relied heavily on manual mold creation and expensive metal tooling. These methods required long lead times and offered limited flexibility once production started. Any design change meant restarting the process, leading to delays and higher costs.

The introduction of CAD software transformed mold design by allowing engineers to plan, simulate, and refine molds digitally. When 3D printing entered the workflow, it became possible to create master models quickly and affordably. These advancements eventually combined into what is now known as repmold—a system built around precision, repeatability, and efficiency.

Why Repmold Is Important in Today’s Manufacturing

Modern manufacturing demands faster delivery, tighter tolerances, and greater cost control. Errors, delays, and material waste can quickly impact profitability. Repmold directly addresses these challenges by offering:

- Consistent and repeatable production results

- Reduced material waste and fewer production errors

- Shorter lead times for molds and parts

- Accessibility for small teams and growing businesses

Repmold allows companies to respond quickly to market changes without committing to expensive tooling, making it a strategic advantage in competitive industries.

How the Repmold Process Works

The repmold workflow follows a clear and efficient sequence:

- Digital Design – A 3D model is created using CAD software or a scanning system.

- Master Model Production – A 3D printer produces the initial physical model.

- Mold Creation – Silicone, resin, or composite material is applied to form the mold.

- Part Replication – The mold is filled with the chosen production material.

- Finishing and Testing – The final part is cleaned, refined, and inspected.

Because the process relies on digital accuracy, it minimizes variations and ensures consistent output across multiple production cycles.

Core Features of Repmold Systems

Repmold systems stand out due to several key features:

- High dimensional accuracy

- Durable molds suitable for repeated use

- Fast production cycles

- Support for complex shapes and geometries

- Compatibility with a wide range of materials

- Easy design updates without restarting the entire process

These features make repmold a flexible solution for evolving product requirements.

Materials Commonly Used in Repmold

Repmold supports a broad selection of materials, allowing manufacturers to choose based on performance needs:

- Silicone

- Epoxy resin

- Polyurethane

- Plastics

- Rubber compounds

- Composites

- Metal-filled resins

This flexibility enables repmold to serve industries such as automotive, aerospace, medical devices, packaging, electronics, and education.

Design Considerations for Effective Repmold Results

Successful repmold design depends on thoughtful planning. Engineers typically focus on:

- Proper wall thickness for strength and flow

- Cooling channel placement

- Smooth material flow paths

- Identification of high-stress areas

Digital simulations help identify potential issues early, reducing redesign costs and improving mold performance before physical production begins.

How Repmold Improves Production Efficiency

By delivering consistent and predictable results, repmold simplifies quality control and reduces production downtime. Manufacturers experience fewer rejected parts, smoother workflows, and better planning accuracy.

Beyond technical improvements, repmold often leads to better collaboration between design and production teams. Faster feedback loops allow ideas to move from concept to physical product with minimal friction.

Industries That Benefit From Repmold

Repmold is widely adopted across multiple sectors, including:

- Automotive manufacturing

- Aerospace development

- Medical and dental applications

- Consumer product design

- Electronics housing and components

- Educational and research institutions

Its adaptability makes it especially valuable for rapid prototyping and low-volume manufacturing.

Repmold and Sustainable Manufacturing

Sustainability is becoming a priority in modern production, and repmold supports this shift. The process uses fewer raw materials, reduces waste, and consumes less energy than traditional tooling methods. Many repmold materials are reusable or recyclable, and localized mold production helps lower transportation-related emissions.

As companies focus on greener operations, repmold aligns well with environmentally responsible manufacturing goals.

Limitations to Consider With Repmold

While repmold offers many advantages, it is not without limitations:

- Some materials may struggle under extreme heat

- Large or high-volume molds can increase costs

- Basic CAD and 3D printing knowledge is required

- Surface finishing may need additional post-processing

However, continuous advancements in materials and automation are steadily reducing these limitations.

The Future Direction of Repmold

Repmold is expected to evolve alongside smart manufacturing technologies. Future developments include:

- AI-assisted mold design optimization

- Smart sensors for monitoring mold performance

- Bio-based and eco-friendly molding materials

- Faster large-scale 3D printing systems

- Increased automation across production workflows

These innovations will further strengthen repmold’s role in next-generation manufacturing.

FAQs About Repmold

What is repmold?

Repmold is a digital manufacturing process that uses 3D design, 3D printing, and modern materials to create molds and parts quickly and accurately.

How does repmold differ from traditional molding?

Repmold is faster, more flexible, and less expensive than traditional metal tooling, especially for prototyping and small production runs.

Is repmold suitable for beginners?

Yes, with basic CAD and 3D printing knowledge, students, startups, and small teams can effectively use repmold.

What materials work best with repmold?

Silicone, resin, polyurethane, composites, and metal-filled resins are commonly used.

Conclusion

Repmold represents a practical shift in how molds are designed and produced. By combining digital precision with flexible materials, it allows manufacturers to move faster, reduce costs, and maintain consistent quality. Whether used for prototyping, testing, or low-volume production, repmold provides a reliable path toward smarter and more efficient manufacturing.

As technology advances, repmold will continue to play a critical role in shaping the future of modern production systems.